The dense, hard surface of porcelain has made polishing a viable alternative to a glazed surface. This means that a tile can be fired, then a polished creating a shine without a glaze.

However polished porcelain may need sealing, where ordinary glazed tiles do not. Unsealed porcelain can attract stubborn stains and can become brittle when in contact with chlorinated water and acids.

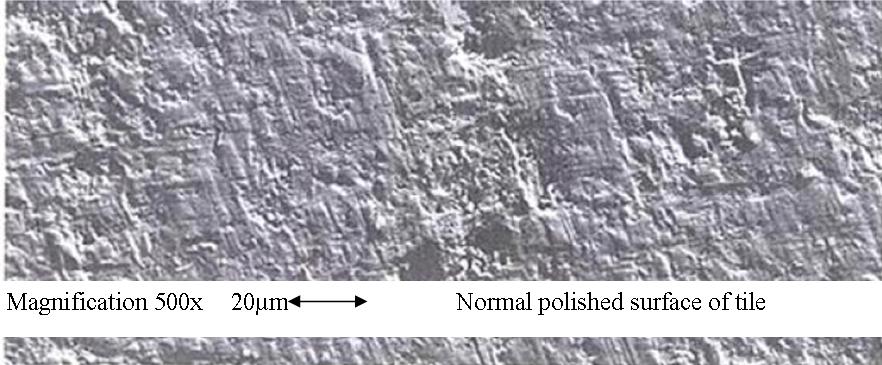

When porcelain is first made, it is not absorbent, but the polishing process for making the unglazed surface shiny cuts into the surface, leaving microscopic pinholes exposed and prone to absorbing stains, in the same way as natural stone tiles. Unless they have a suitable, long-lasting treatment applied by the manufacturer like nano, polished porcelain tiles will need sealing. Porcelain sealants are either solvent-based or water-based. Water based sealants are cheaper, but don't last.

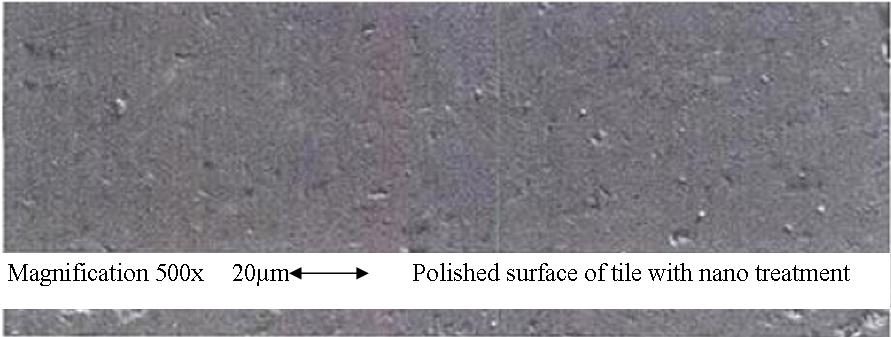

Porcelain tiles with a nano treatment are more dirt and stain resistant, glossier and have more intense colour. Nano treatment is more complex than you might have thought. It consists of applying two different compounds up to ten layers deep to the surface of the tile, polishing between each application and then firing again at 1250ºC.

Here are two microscope images of a porcelain tile surface before and after nano treatment.

A nano polymer compound is pressed into the pinholes of the polished porcelain tile surface. This consists of very light and hard organic nano particles ranging in size from 5nm to1µm. The surface is then polished and a second layer is applied, polished again and a third layer applied. The particles are smaller than the tiny pinholes and cracks in the tiles so they fill these gaps and these pores become permanently sealed.

The second compound applied is a solvent flourine polymer then the tile is polished again. Flouropolymers are characterized by a high resistance to solvents, acids, and bases. With repetitive plating, applied through high pressure sanding and polishing, the nano particles combine with the tile substance to form an organic nano film with a high density and stability, which achieves the distinguishing characteristics of nano treated tiles. Generally at least six layers of polymer application and polishing cycles are completed then a final water wash before high temperature firing.

The technique of application, polishing and firing ensures that the nano particles polymerise (chemically bond) evenly on the surface of the tiles. The high surface sheen of nano tiles creates a protective layer so dirt cannot penetrate the tiles and they are easier to keep clean. The granular material of the protective layer enhances the tiles’ durability and slip resistance making them suitable for both domestic and commercial applications and after firing have a hardness equivalent to that of granite.